Understanding Hard Hat Class: Guide to Selecting the Right Protection

The hard hat is the iconic hero of the workplace. Whether navigating the noisy corridors of manufacturing plants, scaling the heights on a construction site, dodging hazards in utility work, or facing the heat as a firefighter, a hard hat is your first line of defense.

The hard hat is the iconic hero of the workplace. Whether navigating the noisy corridors of manufacturing plants, scaling the heights on a construction site, dodging hazards in utility work, or facing the heat as a firefighter, a hard hat is your first line of defense.

Continue reading as we look at hard hat classes, examine the difference between Type 1 and Type 2 hard hats, and provide tips on finding the right hard hat fit for your industry. Join us as we explore the history and the specific uses of hard hats, and how this workplace essential helps to ensure workers go home safe every day.

Quick Links

- Hard Hat History

- Hard Hat Classes

- Hard Hat Types

- Classifications Across Industries

- Types/Classifications and Use – Chart

The History of Hard Hats in the Workplace

While the hard hat may be a common feature today, head protection wasn’t a part of the workplace until the 1930s. Developed by businessman and inventor Edward W. Bullard, the original “Hard Boiled Hat” was constructed from canvas and leather and was inspired by military helmets worn on the battlefield during World War I.

First adopted by the mining industry in the 1920s, hard hats were optional on the worksite until construction of the Hoover Dam began in 1931. The hard hat became even more widely used during the construction of the Golden Gate Bridge when workers began wearing headgear to protect themselves against falling rivets.

Hard hat classifications used today, such as standards like ANSI Z89.1, were first established in the 1950s. The most significant classifications were developed in the 1980s, where different types like Type 1 and Type 2 hard hats and “classes” based on electrical protection were clearly defined.

The Important Role of Hard Hat Classes in Preventing Injuries

Hard hats are crucial for workplace safety, but the numbers tell us not enough workers are wearing them.

- Head injuries: More than 1,000 workers in the United States die from head injuries on the job each year.

- Hard hat use: Only 16% of workers who sustained head injuries were wearing hard hats.

- PPE purchases: Head protection accounts for only 3% of personal protective equipment purchases, despite head injuries constituting over 20% of workplace injuries.

- Injury types: Traumatic brain injuries (TBI) are the most common type of head injury sustained at work.

- Injury causes: The majority of slip, trip, and fall-related head injuries occur from falls of just six feet or less.

These figures underline a clear message: there’s a critical need to boost hard hat usage to better protect workers from preventable injuries.

The Difference Between Hard Hat Types and Classes

Knowing the difference between Type 1 and Type 2 can make all the difference in your safety depending on your job. Hard Hat Classes help determine safety with electrical conditions.

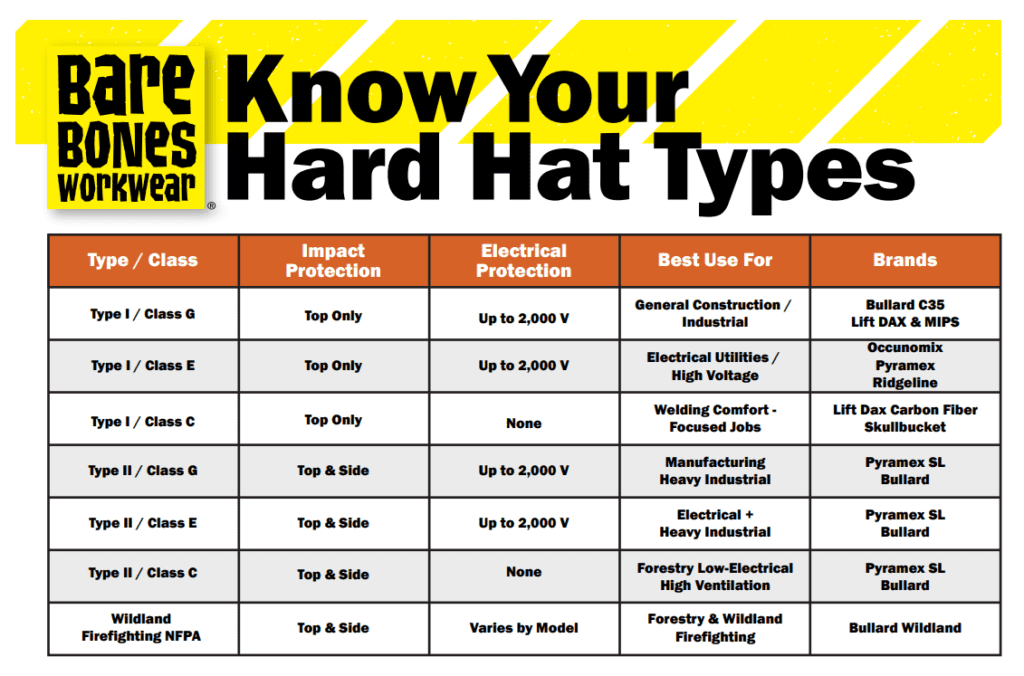

Hard Hat Types (Impact Protection)

- Type I

- Protects from top impact only (e.g., debris or tools falling from above).

- Common in U.S. construction and general industry.

- Type II – a broader layering of safety protection

- Protects from top and lateral (side, front and back) impacts.

- Required in environments with risk of blows or collisions from the side (manufacturing, tree trimming, heavy industry, or working at heights).

Hard Hat Classes (Electrical Protection)

- Class G (General)

- Tested to 2,200 volts protection.

- Suitable for most construction and industrial work where electrical risk is possible but not primary.

- Class E (Electrical)

- Tested to 20,000 volts protection.

- For electrical work, utilities, or live wires. This is the go-to class for electricians, linemen, and high-voltage environments.

- Class C (Conductive)

- No electrical protection.

- Often lighter, better ventilation (e.g., aluminum or vented styles).

- Good for jobs where heat dissipation and comfort matter more than electrical hazards.

Hard Hat Classifications Across Industries

From factory floors to fiery frontlines, the right hard hat can literally be a lifesaver. Here’s how these vital pieces of safety gear fit into the day-to-day of different industries:

Manufacturing, Construction, and General Work Conditions

Typically Type I, Class G. Provides overhead protection at job sites with occasional electrical exposure.

In the manufacturing sector, workers face hazards from automated machinery and moving equipment. Hard hats protect against head injuries from overhead objects and the impact from machinery malfunctions. These helmets are essential for absorbing shocks and reducing the impact of debris.

No hard hat? No entry. Construction zones are ground zero for airborne debris and high-altitude risks. Hard hats are mandatory here, providing crucial protection against injuries from impacts, falls, and even bumps against fixed objects. They are designed to cushion and distribute the force of impacts, safeguarding workers from potentially fatal injuries.

Utility Work

Require Type I or II, Class E for maximum electrical protection.

For those who keep the lights on and the water running, hard hats are crucial, especially when it comes to dodging electrical hazards. Hard hats for this sector are specially designed with non-conductive materials, providing an extra layer of safety against electrical shocks and burns. These helmets often include features like face shields for additional protection.

Wildland Firefighting

Often Type II, Class G or E, with chin straps and heat resistance (must meet NFPA 1977 for wildland helmets).

Firefighting requires helmets that can withstand extreme conditions—heat, falling debris, and chemical exposure. Firefighter helmets are equipped with materials that offer thermal resistance and have the ability to add face shields, chin straps, lights or neck protectors to guard against heat and embers.

Welding / Grinding / Outdoor:

Class C can be useful where electrical risk is absent but cooling or specialty features (like visors, shades, or cowboy-style brims) matter.

Special Topics

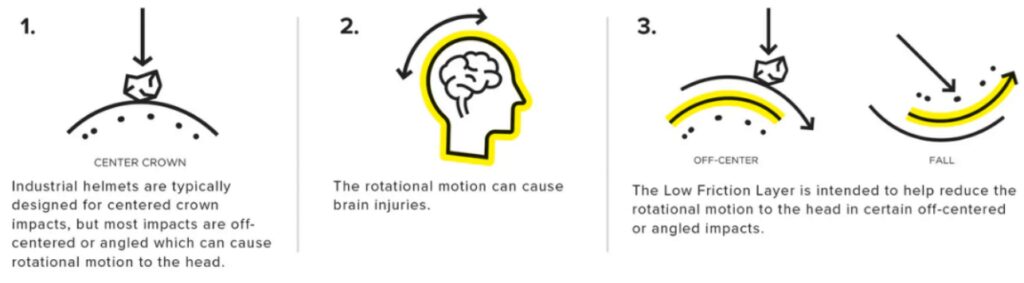

Mips© safety system provides exceptional protection beyond the basic ANSI ratings, The Mips® safety system features a low-friction layer inside a safety helmet or hardhat that allows a multi-directional movement of 10-15mm on certain angled impacts, intended to help reduce rotational force to the head. The Lift MIPS is a Type I/Class G hard hat.

Click here for a short video on how it works. MIPS makes the impact to your favor. BareBones WorkWear® offers this feature with the Lift MIPS hard hat.

Bump Caps – these are not ANSI rated, and not really considered a hard hat. Some folks wear them for light protection in a roof attic or for low overhangs. They resemble a cheap baseball hitters cap.

Chin Straps – Chin straps aren’t just for compliance—they play a vital role in retaining head protection during slips, trips, or sudden movements. Even the most protective helmet may shift or fall, rendering it ineffective. OSHA’s recent policy change—moving from standard hard hats to safety helmets with chin straps—sets the tone for industry best practices and signifies a broader regulatory shift. The good news is BareBones WorkWear carries inexpensive chin straps as an add-on feature, and a variety of Bullard, Pyramex and Lift Hard Hats with their own chin straps.

Cooling Accessories – From sunshades to cooling sweatbands, there is a variety available from Radians, Occunomix and Zangear.

BareBones WorkWear® is Your Hard Hat Headquarters

From factory floors to fiery frontlines, the right hard hat can literally be a lifesaver. Every industry has its hazards, and at BareBones WorkWear®, we’ve got the hard hat for every challenge. From manufacturing to firefighting, our selection ensures you’re covered with the right gear for every job’s demands.

At BareBones WorkWear®, we carry a wide range of hard hats suitable for any job. Our inventory includes top brands like Bullard, Lift, Pyramex, Radians, Skullbucket and Occunomix, each offering unique features tailored to specific industry needs—from standard construction models to high-tech options designed for electrical safety in utilities.

Hard Hat Types/Classifications and Use

Visit any of our 10 locations to explore our selection, get expert advice, and ensure you purchase a hard hat that meets industry standards and fits comfortably.

Don’t take any chances when it comes to safety. Protect your head with the best from BareBones WorkWear®.